Foil stamping paper, also known as gilding paper, bronzing paper, or anodized foil, is widely used in hot stamping printing to give products a shiny, metallic finish. Whether you are in packaging, fashion, electronics, or printing industries, understanding foil stamping paper's properties, applications, and usage tips will help you choose the perfect material for your needs.

What Is Foil Stamping Paper?

Foil stamping paper is a polyester (PET) film coated with multiple chemical layers, including a reflective aluminum layer formed by vacuum metallization. The PET base usually has a thickness of 12 microns, providing strength and heat resistance. The aluminum layer creates a metallic shine, ideal for decorative effects on various substrates.

Key Characteristics of Foil Stamping Paper

- Optimal Hot Stamping Temperature: 95°C to 135°C, depending on substrate.

- Available in Different Sizes: Standard roll size is 0.64m x 120m; custom lengths like 240m or 360m are available.

- Types of Stamping Areas: Suitable for small strokes (small area), 6x6 mm (medium), and 10x10 mm (large area) stamping.

- Storage Recommendations: Store at room temperature, avoid moisture, pressure, and direct sunlight.

Applications of Foil Stamping Paper

Foil stamping paper is versatile and widely used in various industries, including:

- Textiles & Apparel: High-end fashion fabrics, T-shirts, bags, casual shoes.

- Plastics: ABS, PVC, PMMA products like electronic parts, pens, clocks.

- Packaging: OPP laminated cigarette packs, wine boxes, gift boxes, and mooncake boxes.

- Cosmetics & Daily Necessities: PP, PE packaging for cosmetic boxes and household goods.

- Electronics: DVDs, VCDs, speakers, transparent panels, home appliances.

- Glass & Metal: Cosmetic bottles, wine bottles, nameplates, teacups.

- Leather: PU leather, imitation leather for shoes, cases, and book covers.

- Special Applications: Buddhist incense paper, various stamping machines.

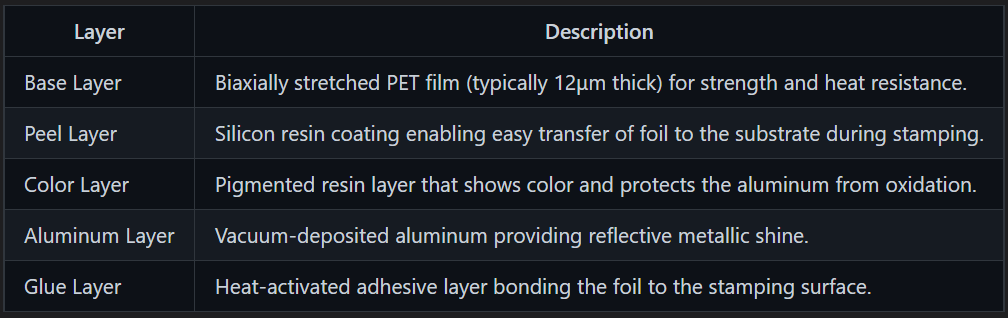

Structure of Foil Stamping Paper

Foil stamping paper consists of five layers, each with a specific function:

How to Choose the Right Foil Stamping Paper?

Selecting the appropriate foil stamping paper depends on several factors:

- Substrate Material: Paper, plastic (ABS, PP, PVC), fabric, leather, wood, metal.

- Stamping Method: Flat hot stamping, pneumatic, automatic continuous stamping.

- Stamping Area Size: Suitable for small lettering, medium, or large area designs.

- Production Speed: Manual, semi-automatic, or high-speed automatic processes.

- Color and Brightness: Gold, silver, matte, metallic, or colored foils, based on design needs.

- Post-Processing: Whether reprinting or coating is required after stamping.

- Product Use: Indoor or outdoor durability requirements.

Best Practices for Using Foil Stamping Paper

- Test Hot Stamping Temperature: Start within 95-135°C range and adjust for substrate.

- Ensure Proper Pressure and Timing: Typical pressure is 4 kg/cm²; time varies by material.

- Storage: Keep foil rolls upright in a cool, dry, ventilated place, away from sunlight.

- Avoid Rubbing After Stamping: Let the foil cure for at least 24 hours before washing or handling.

- Select Correct Adhesive Type: Water-based or oil-based glue layers for different substrates.

- Use Suitable Hot Stamping Machines: Pneumatic, semi-automatic, or automatic, depending on scale.

Common FAQs About Foil Stamping Paper

Q1: What are the standard sizes of foil stamping paper rolls?

A: Common sizes include 640mm x 120m (China/Japan), 610mm x 122m (Germany), and larger sizes for leather or fabric.

Q2: What thicknesses are available?

A: PET base usually 12μm; 19μm and 25μm are used for large-area hot stamping.

Q3: What colors can foil-stamping paper come in?

A: Besides gold and silver, popular colors include red, green, blue, black, bronze, metallic brushed effects, and pearlescent finishes.

Q4: Which substrates can be stamped using foil stamping paper?

A: All kinds of paper, plastics (PC, PS, PP, PET, PVC, PMMA, ABS), leather, fabrics, metal, and glass.

Q5: How long can foil-stamping paper be stored?

A: Stored properly (cool, dry, ventilated), shelf life can be up to two years

Why Choose Foil Stamping Paper for Your Products?

- Stunning Visual Appeal: Metallic shine and bright colors attract consumer attention.

- Versatility: Works on many substrates, suitable for various industries.

- Cost-effective: Simple process with low production cost compared to other printing methods.

- Environmental Safety: Non-toxic, eco-friendly materials are increasingly available.

- Wide Range of Designs: From small, detailed logos to large decorative areas.

- Compatible with Various Machines: Manual to fully automatic production lines.

Contact Us for Professional Foil Stamping Solutions

If you are looking for a durable foil stamping machine for textile ribbons. Reach out today for a free consultation and quote:

📧 Email: info@iprintingpress.com

🌐 Website: www.iprintingpress.com

Let us help you create dazzling products that stand out in the market!