Hot Foil Stamping Machine for Label Ribbons & Elastic Tapes – Reliable Performance

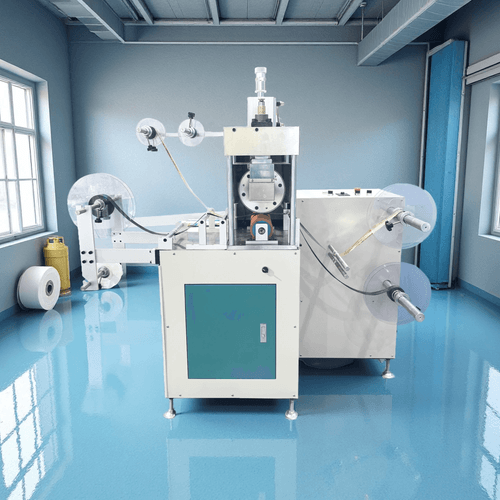

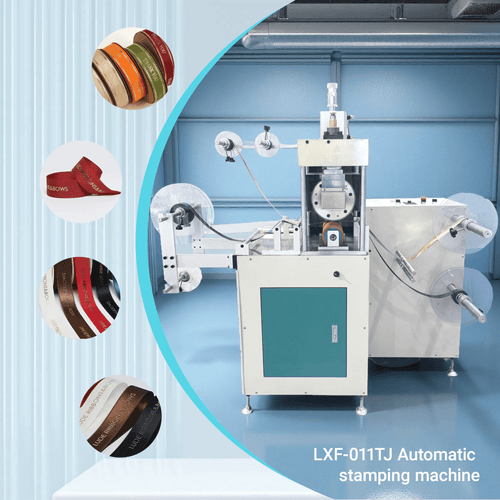

Model: LXF-011TJ

Pressure Area: 1-26cm (adjustable for all roll widths)

Max Temperature: 300°C (handles tough materials)

Pressure Speed: 20M/min (steady, high-speed output)

Power: 220V/3KW (efficient and reliable)

Net Weight: 250KG (solid yet manageable)

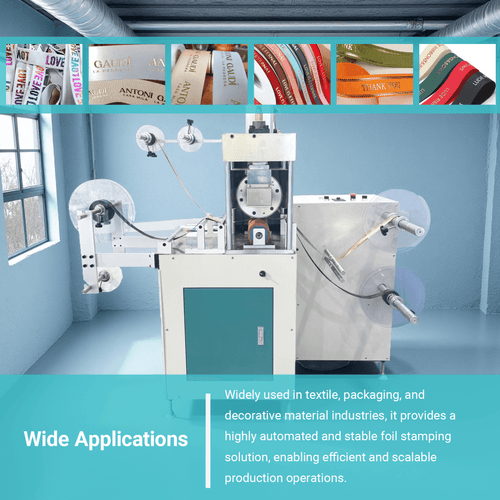

Applications: Perfect for 𝗿𝗶𝗯𝗯𝗼𝗻 𝗳𝗼𝗶𝗹 𝘀𝘁𝗮𝗺𝗽𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲 tasks—cotton tapes, elastic tapes, label ribbons, and more. Delivers sharp foil stamping on multi-line ribbons with speed and quality.

Get clean, lasting foil prints on your ribbons and tapes with this 𝗵𝗼𝘁 𝗳𝗼𝗶𝗹 𝘀𝘁𝗮𝗺𝗽𝗶𝗻𝗴 𝗺𝗮𝗰𝗵𝗶𝗻𝗲. Contact us for pricing and start stamping today!

Worry about the machine's quality and our service? Please see what our clients say, click here.

: LXF-011TJ Hot Foil Stamping Machine – Your Go-To for Stunning Ribbon Printing

Say goodbye to plain, boring ribbon designs with the LXF-011TJ hot foil stamping machine. This ribbon foil stamping machine makes your ribbon printing stand out, bringing a sharp, shiny finish to every roll—whether it’s satin ribbons, cotton labels, elastic tapes, or custom designs. Compact enough to fit your workspace, affordable for any budget, and built to last, this foil stamping ribbon machine combines fast performance with quality you can count on. It’s the tool you need to turn simple ribbons into eye-catching pieces that grab attention.

Designed for ease and impact, the LXF-011TJ makes the foil ribbon printing machine work feel effortless. Want to know how to use a hot foil stamping machine? It’s simple—load your roll, set your design, and let it stamp crisp, glamorous foil details at high speed. Curious about how foil stamping works? This machine presses heated foil onto your ribbons, leaving a bold, durable mark that shines. From multi-line ribbon runs to single-label jobs, it handles ribbon hot stamping machine tasks with precision, making every piece look polished and professional.

Why settle for ordinary when you can have standout results? The LXF-011TJ isn’t just another foil stamping machine for ribbons—it’s a reliable partner for small shops, label makers, and ribbon pros looking to impress. Whether you’re crafting invitations with a foil stamping machine for an invitation vibe or scaling up with hot foil stamping machines for sale, this machine delivers. Ready to see how to do foil stamping that turns heads? Send us an inquiry today and get the full scoop on this foil-stamping equipment—your ribbons deserve to shine!

Why It’s a Cut Above:

- Shine That Lasts: Turns dull rolls into dazzling designs with this hot foil stamping machine for ribbon.

- Fits Anywhere: Compact size means it works in tight spaces—no bulky hassle.

- Quick & Steady: High-speed stamping keeps your foil ribbon printer moving without slowdowns.

- Built Tough: Durable enough for daily use—your ribbon stamping machine won’t quit.

- All-Rounder: From elastic tapes to satin, this hot stamping ribbon printing machine nails every job.

Who It’s Made For:

- Ribbon Crafters: Perfect for adding flair with a foil machine craft touch.

- Label Experts: Crisp, fast foil stamping machine for sale results for branding.

- Busy Workshops: A ribbon foil printing machine that keeps up with demand.

Don’t let your ribbons blend into the background. With the LXF-011TJ hot foil stamping machine price that fits your budget and the performance that delivers, it’s time to make your designs pop. Contact us now and get rolling with ribbon printing that customers can’t ignore!

Hot foil stamping is a kind of printing technology.

Samples can be done by this machine.

Foil stamping refers to the temperature and pressure of the anodized foil hot stamping on the substrate surface of the process.

Anodized hot stamping graphics and text present a strong metallic luster, bright colors, and eye-catching, never-fading. In particular, gold and silver anodized aluminum, with its magnificent, exquisite, and elegant decoration, embellished the surface of the printed matter. Enhanced the artistic quality of the printed matter, played a prominent role in Publicity Effect; Its brightness greatly surpassed the printing of gold and silver, so that the product has a high-grade feeling and gives people the enjoyment of the United States. Meanwhile, due to the excellent physical and chemical properties of anodized materials, it play a role in protecting printed materials, so bronzing technology is widely used in high-grade and exquisite packaging and decoration trademarks, calendars, book covers, and other printed materials.

Secondly, anodized hot stamping covers a wide range, from general book covers, trademark patterns, advertising, plastic products, to daily department stores, from paper to leather, cotton cloth, etc. The workpiece can be packed and transported immediately after bronzing. Therefore, foil stamping technology is widely used. The hot stamping application is still expanding.

A screen printing machine is a machine that prints words and patterns on flat or regular surfaces. The basic principle of its work is: First of all, installa screen printing plate (using the photographic plate-making method to make the screen holes on the screen printing plate as through holes instead of blocking the screen holes on the picture and text parts). Printing through the Squeegee, so that the ink through the pattern part of the mesh transfers substrate, the same graphics and text as the original.

Silk Screen Printing is widely used in printing and dyeing, electronics, applied arts, commercial decoration, ceramic decoration, publishing, and printing industries.

It is widely used for graphic or flat surface printing patterns such as Cups, electronic products, cosmetics bottles, street, penholders, toys, mineral water bottles, shampoo bottles, etc.

Three elements of hot foil stamping technology

1. Time (T), 2. temperature (T), 3. pressure (P)

These three elements are interrelated and mutually binding. As we all know, the bronzing paper needs to absorb a certain amount of heat energy (Q) under certain pressure, which can make stamping paper ink and additives to a certain shape, and hot stamping to the surface of products

Where the Q and P in certain external conditions are inversely proportional. That is, in stamping a product, if the bronzing paper in a bronzing position can absorb a lot of heat, this bronzing requires very little pressure to iron the product well

And the relationship between T.T. and Q. is:

Q = r * t (T-t 0)(R is constant and t O is room temperature)

So t and t are inversely proportional to each other, under certain external conditions, under certain pressure, to produce a good product. If you use a very short pressure time, then the hot stamping temperature must be set very high; if you use a hot stamping temperature low, its bronzing pressurization time is set very long.

To foil-stamp a good product, it must have the following conditions:

1. Have a good hot foil stamping machine

A. General stamping machine consists of five parts: the working part, debugging part, mooring part, Airway part, and electrical control part

B. A good foil stamping machine has five parts, a reasonable design, a compact structure, good performance, and a long service life

2. Choose the right gilding paper

A. Bronzing paper has four layers: P paper base layer, ink layer, aluminum powder layer, and hot-sensing pressure melts layer

B. The drawing of each layer of bronzing paper:

P-BASE is the basis of ink adhesion, using p-high strength and high toughness, enough to ensure the stability and continuity of bronzing paper

Ink Layer is to achieve the bronzing color

The aluminum powder layer is aluminum powder vacuum plating on bronzing paper, increasing the brightness of bronzing products